Class Project (ME 444) to Design BD-1 Toy in 6 Weeks

Timeline: 11/2025 - 12/2025

Skills Used: CAD (Creo Parametric), Engineering Design, Rapid Prototyping, ESP32s motor control, ESP32s Sensor Interfacing, Engineering Analysis, Soldering, Protoboard Circuit Design

Goal: Build Marketable Toy from Scratch

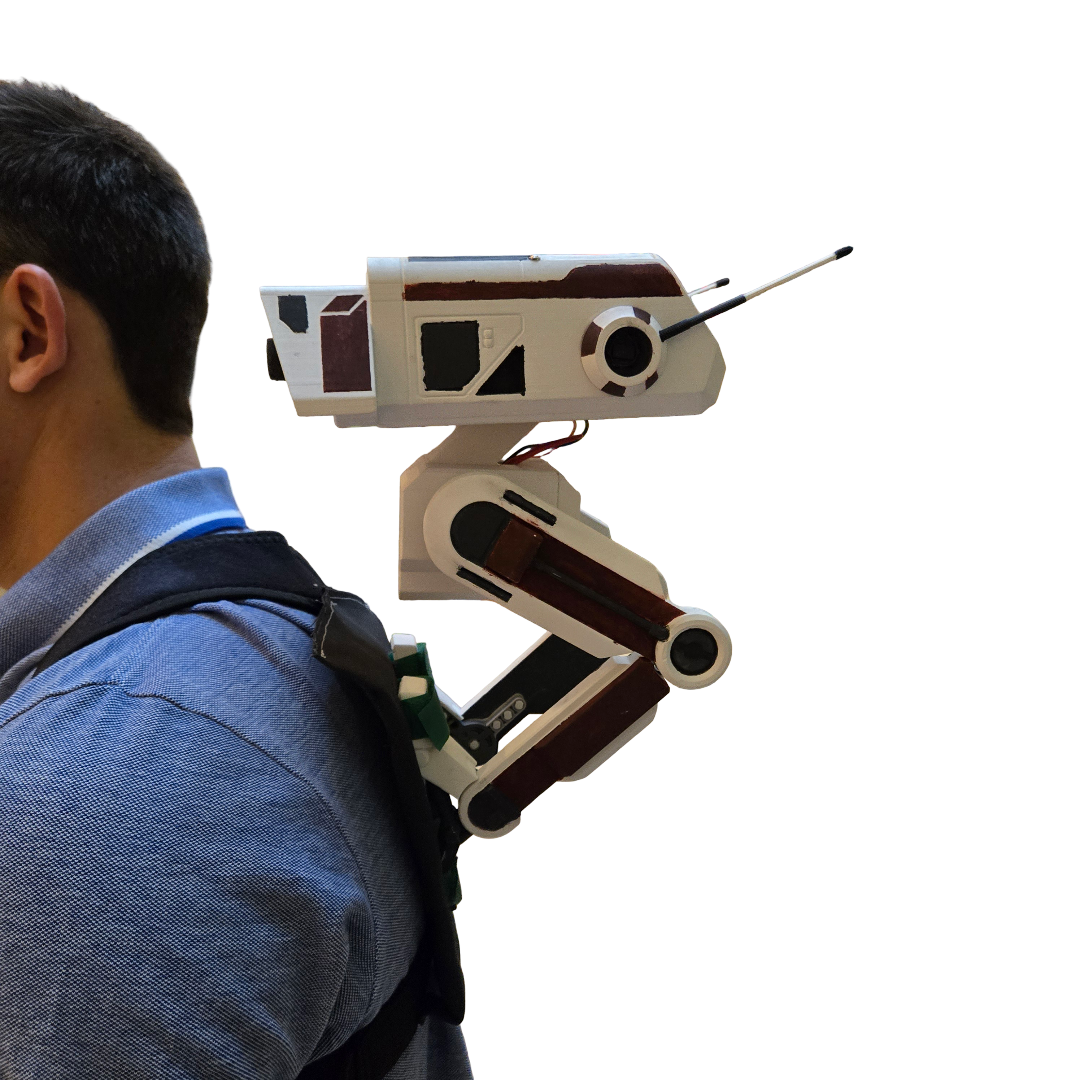

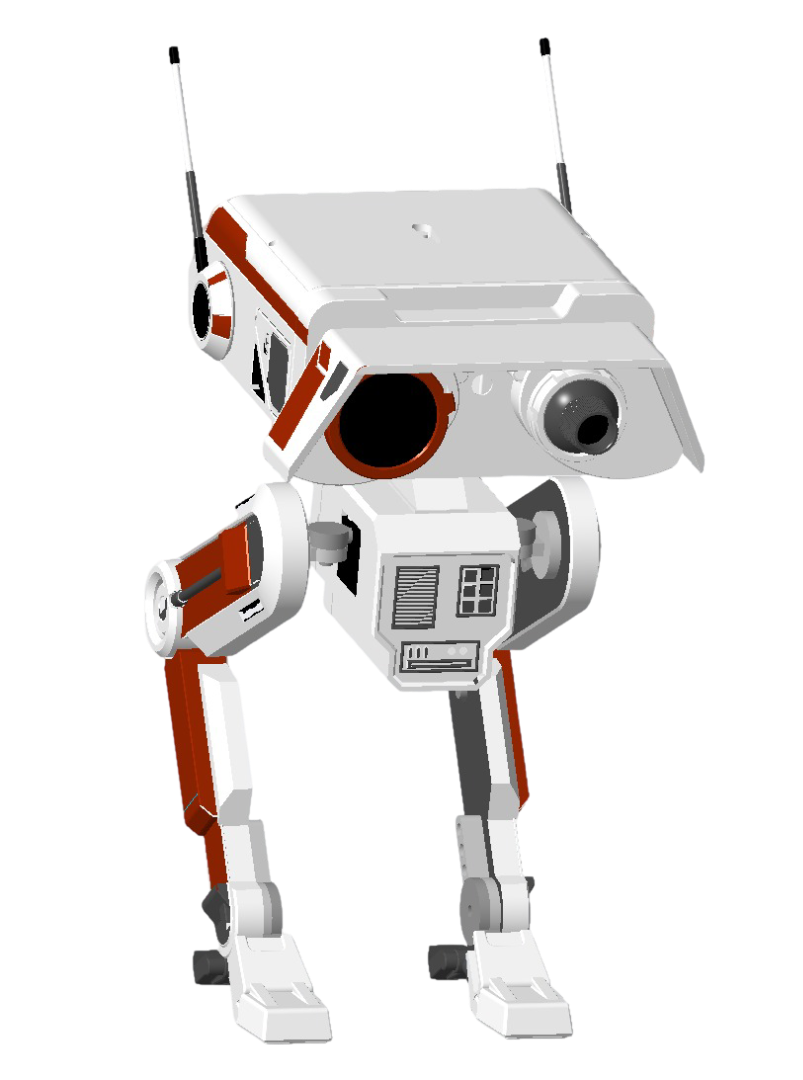

BD-1 (Credit to GameRadar.com)

The goal of this project was to build and sell a toy to a worldwide audience with a 4-person team. When brainstorming ideas for our final design, we settled on making a spin-off of BD-1, a droid from the Star Wars video game Star Wars Fallen Order. We decided to choose BD-1 due to its cuteness and feasibility of construction over 6 weeks.

Our goal was to replicate key features of BD-1 to make him come to life in toy form, using rapid prototyping methods and electronics. Then, at the end of the semester, we would demonstrate our fully working toy at the ME 444 Toy Design Fair. Since we were team 22, we decided to name our product BD-22.

Design Process

Conducted Market Analysis on existing BD-1 toys

Planned 6-week design timeline leading up to Toy Fair

Built medium-fidelity prototype of subsystems

Redesigned subsystem based on prototype performance

Integrated subsystems to test overall performance

Painted and fine-tuned before Toy Fair

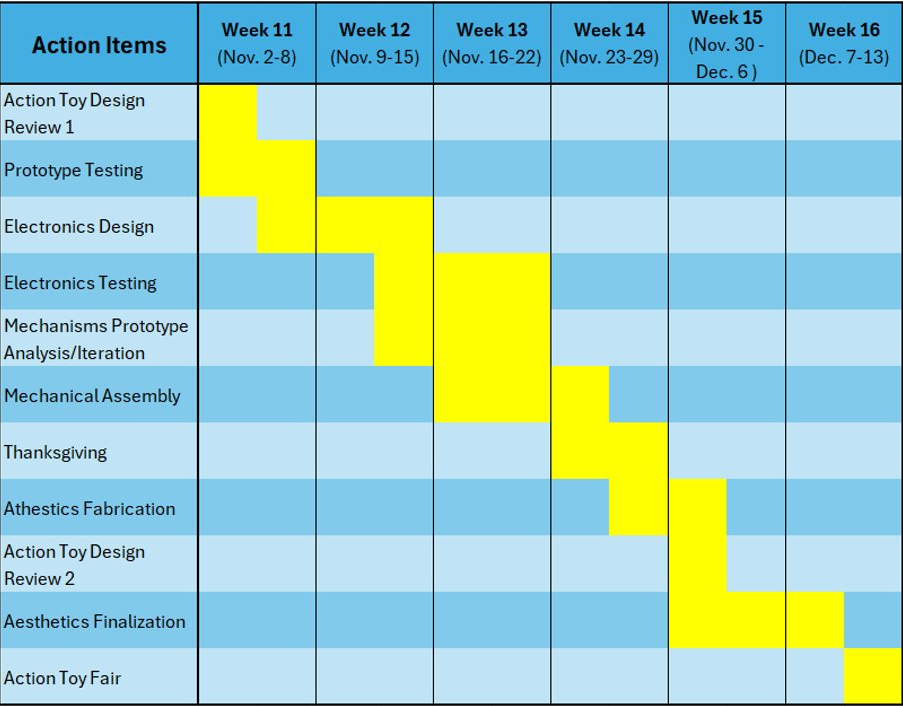

BD-22 Initial Design Timeline

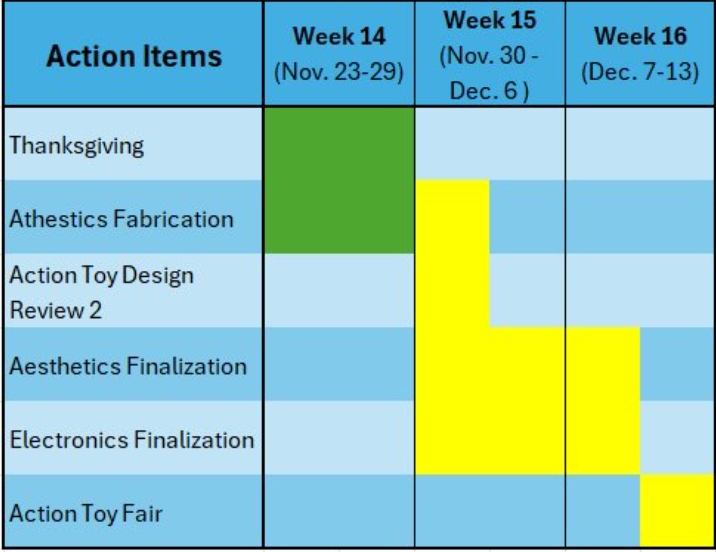

BD-22 Midterm Design Timeline

Subsystem Prototypes

Below are prototypes of four of our five subsystems:

Head motion gimbal

Antenna bevel gears

Leg Joints

Face Tracking/Electronics

Shoulder Mounting (not finished because of strap shipping delay)

I made a leg over center mechanism prototype, a face tracking algorithm prototype, and the electronics prototype. The team decided that the Lego prototype Poseability would make it easier to compensate for design error in the three weeks before the Toy Fair.

Electronic Circuit Prototype

Leg Over-Center Prototype

Leg Lego CAD

Head Gimbal Prototype

Results

The face tracking worked well enough for tracking faces side-to-side, with some oscillation.

The antenna bevel gear mechanism worked almost perfectly. They were programmed to perform a set routine when a face was detected

Face Tracking and Antenna Movement

The shoulder mounting strap and mechanism supported BD-22 in the configuration shown in the photo.

The only downside to this design was the time it took to put BD-22 on the user’s back—securing him using the velcro straps took two people around 45 seconds.

The legs move successfully back and forth between the standing and shoulder mount pose. However, the posability makes it the robot somewhat unstable over time and care has to be taken to get the robot into the right position for standing.

Shoulder Mounting

The head gimbal worked tilting the head up and down and turning side to side with a test weight. However, tilting did not work with all components installed in the head, likely due to unexpected friction.

The servo and camera board were wired to the ESP32s microcontroller on protoboard for a lasting connection. The battery was housed in a compartment in the middle body segment.

Electronics in Head

Next Steps

Some next steps I would recommend are:

Upgrading head turning and tilting servos to DC motors with higher torque and with encoders/potentiometers for more robust face tracking

Redesigning legs without lego joints for higher stability (perhaps utilizing springs or compliant mechanisms)

Redesigning head with electronics accessibility in mind and user ergonomics in mind

Performing design for assembly analysis for injection molded parts

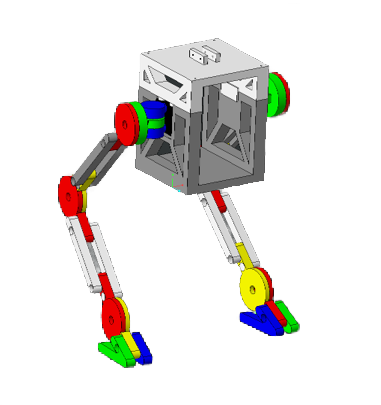

BD-22 CAD Screenshot